How AI is Revolutionizing the Automotive Industry: Driving the Future of Mobility

AI in Automotive: From Hype to the Highway in 2025

For years, the promise of Artificial Intelligence in the automotive world felt like science fiction – a distant future of flying cars and fully autonomous vehicles. But the hype has given way to reality. In 2025, AI is no longer a far-off concept; it’s the engine driving the industry’s most significant transformation. We’ve moved beyond the stalled dream of Level 5 autonomy and into the era of the Software-Defined Vehicle (SDV).

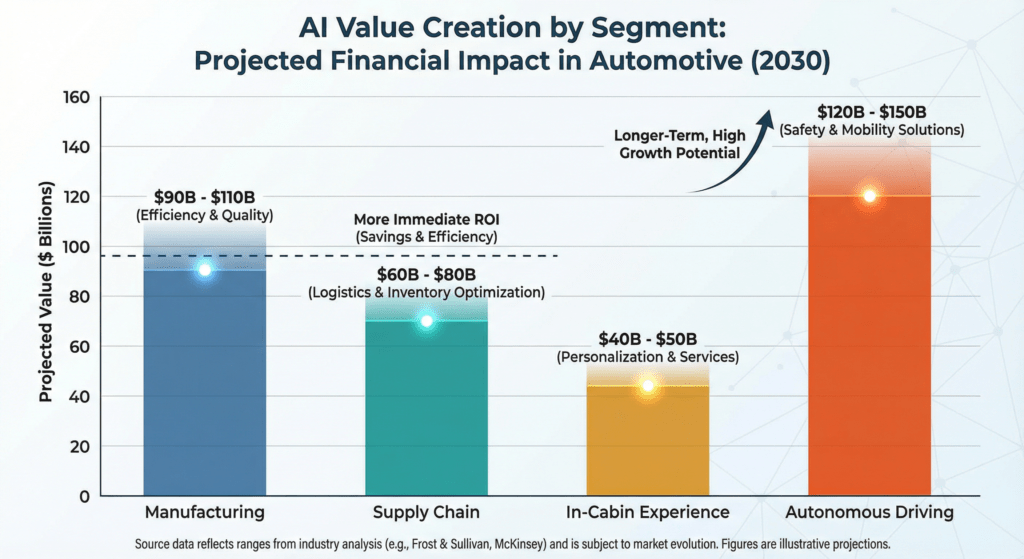

The financial impact is staggering, with the global market for AI in automobiles projected to surge from $43 billion in 2025 to $238 billion by 2030. This growth isn’t just about self-driving features. AI is now fundamentally reshaping how vehicles are designed, built, experienced, and maintained. This blog explores the real-world applications of AI that are defining the automotive landscape today – from the design studio to the factory floor and into the driver’s seat.

How is Generative AI Revolutionizing Automotive Design?

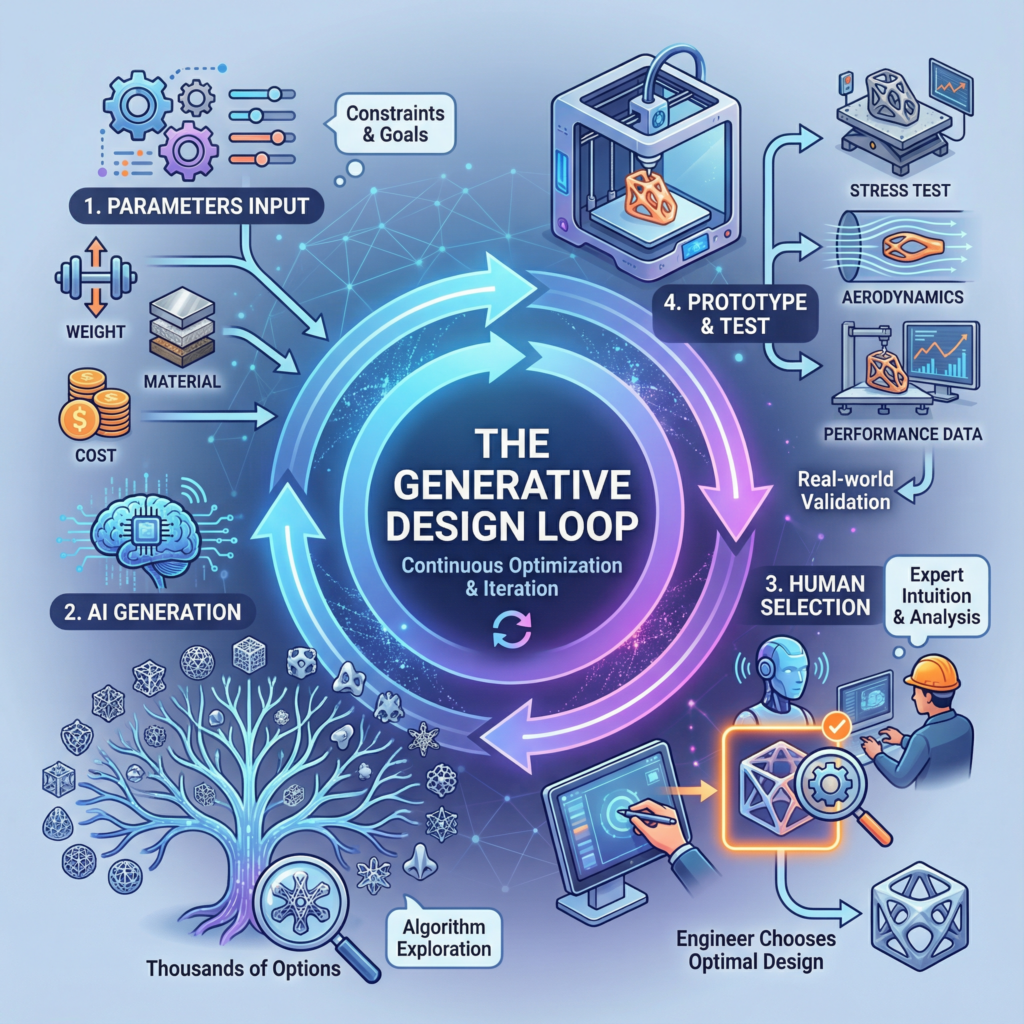

The days of slow, human-led design iterations are over. Generative AI has emerged as a transformative force, allowing engineers to create lighter, stronger, and more efficient components in a fraction of the time.

Generative Design in Action This technology uses algorithms to explore thousands of design permutations for a single part based on specified constraints like material, weight, strength, and cost. Instead of an engineer manually drafting a component, they now act as a curator, setting goals for the AI, which then generates hundreds of optimized, often organic-looking, designs that a human would never conceive. This process can shorten component development timeframes by 10-20%.

General Motors x Autodesk A landmark example is the collaboration between General Motors and Autodesk to redesign a simple seatbelt bracket. By inputting the design parameters into a generative design algorithm, they produced over 150 potential designs. The final, 3D-printed part was a single piece that replaced an assembly of eight components, resulting in a bracket that was 40% lighter and 20% stronger than the original. This project demonstrated the immense potential for mass reduction across the 30,000+ parts in a typical vehicle.

“Text-to-Design” Looking ahead, the industry is experimenting with “Text-to-Design” prototypes. This emerging technology allows designers to use natural language prompts to generate initial concept car sketches, further accelerating the creative process and pushing the boundaries of vehicle aesthetics.

What is Manufacturing 4.0’s “Lot Size One” Revolution?

AI is overhauling the factory floor, moving the industry from mass production toward hyper-personalization. The ultimate goal is “Lot Size One,” where manufacturers can customize every vehicle on the assembly line to individual customer specifications without sacrificing production speed.

Digital Twins and Predictive Power Automakers are now creating “digital twins” – virtual replicas of their factories – to simulate and predict bottlenecks before they occur. By feeding real-time data into these AI models, plant managers can optimize workflows, manage equipment, and prevent downtime. AI-driven predictive maintenance can cut unscheduled downtime by 35-50% by monitoring machinery for signs of wear and scheduling repairs proactively.

Flawless Quality with Computer Vision Human inspectors can’t catch every microscopic flaw, but AI can. Computer vision systems now scan vehicles on the assembly line, detecting tiny paint imperfections, weld defects, and surface anomalies with superhuman accuracy. These systems can inspect 100% of vehicles, flagging issues in real time and dramatically reducing warranty claims and end-of-line rework. For example, some AI inspection tools have improved defect detection accuracy by up to 10 times compared to general-purpose machine learning methods.

How is AI Crafting the In-Cabin Experience?

The modern car is becoming less of a machine and more of a companion. AI is at the heart of this shift, transforming the dashboard into an intelligent, context-aware co-pilot.

From Voice Commands to Conversational AI In-vehicle voice assistants are evolving from rigid command-based systems (“Call Mom”) into sophisticated conversational agents powered by Large Language Models (LLMs), similar to ChatGPT. These AI assistants understand context and nuance. A driver can say, “I’m hungry,” and the system will suggest highly-rated restaurants along the route, check for road closures in real-time, and even help manage the infotainment system without the driver’s hands leaving the wheel.

Driver Monitoring Systems (DMS) for Safety and Comfort With distracted driving causing thousands of fatalities annually, AI-powered Driver Monitoring Systems (DMS) are becoming a critical safety feature. Using in-cabin cameras and sensors, these systems track driver behavior in real-time, detecting signs of fatigue like eye closure, head nodding, or yawning, as well as distractions like phone usage. If the system detects drowsiness, it can do more than just sound an alert; it can suggest a rest stop or adjust cabin lighting and music to increase alertness.

How Does AI Bolster Supply Chain Resilience and Maintenance?

The automotive industry has been plagued by supply chain disruptions, from chip shortages to geopolitical conflicts. AI is now being deployed to create more resilient and proactive operations.

Predictive vs. Proactive Maintenance While predictive maintenance uses sensor data to fix parts before they break, proactive design goes a step further by using AI to design components that are less likely to fail in the first place. This shift reduces long-term warranty costs and improves vehicle reliability.

AI-Powered Risk Management Modern AI systems provide a crucial layer of intelligence for supply chain management. These platforms analyze thousands of data points in real-time – from geopolitical news and weather patterns to labor disputes and shipping delays—to predict disruptions weeks in advance. This allows automakers to proactively switch suppliers or reroute shipments, maintaining production continuity while competitors react to crises after they’ve already hit. Some companies have seen a 30% reduction in disruptions by implementing such AI-driven strategies.

What is AI’s Role in Software-Defined Vehicles (SDVs)?

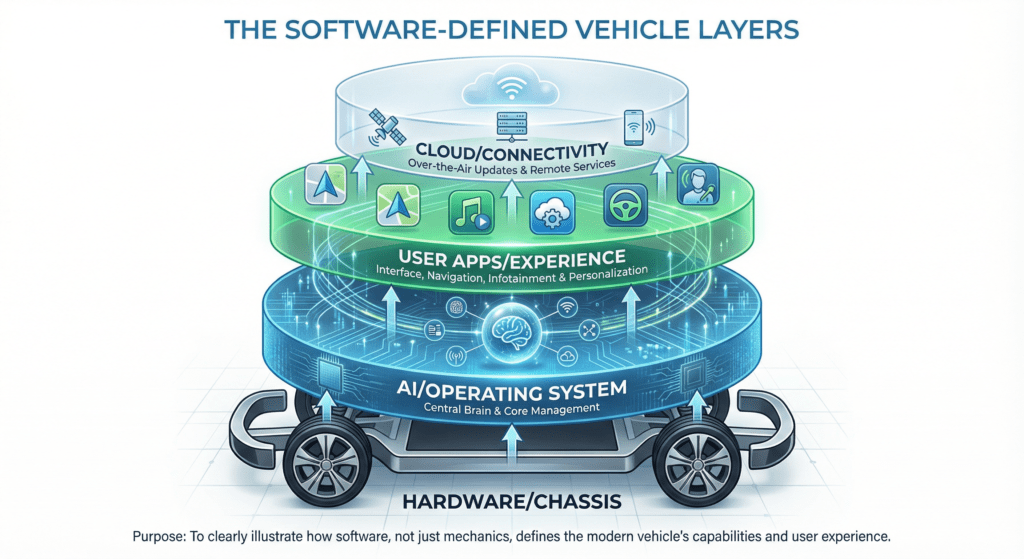

The modern vehicle is a “computer on wheels,” and its value is increasingly defined by its software. AI is playing a hidden but heroic role in the development of these Software-Defined Vehicles (SDVs).

AI as a Coding Assistant Generative AI now functions as a “copilot” for software engineers, automating monotonous tasks and generating initial code for review. It is estimated that these AI assistants can write 30-40% of the code for modern vehicles, which significantly speeds up development cycles, bug fixes, and the deployment of over-the-air (OTA) updates.

Comparison: Traditional Automotive vs. The AI-Driven Era

The shift from a mechanical to a digital-first approach is reshaping every aspect of the automotive industry.

| Feature | Traditional Auto Industry | AI-Driven Industry (2025) |

|---|---|---|

| Maintenance | Reactive (“Fix when broken”) | Predictive (Sensors forecast failure) |

| Design | Human-led, slow iteration | Generative, thousands of options in hours |

| Production | Mass production (Uniformity) | “Lot Size One” (Hyper-customized) |

| Quality Control | Manual spot checks | 100% Computer Vision inspection |

| In-Cabin UX | Rigid voice commands | Conversational AI companions |

| Supply Chain | Reactive to disruptions | Proactive risk prediction |

The Road Ahead: Sustainability and the Future in 2026

As we look toward 2026, the focus is sharpening on sustainable AI. A key application is the optimization of Electric Vehicle (EV) performance. AI is now used to manage battery health by analyzing temperature, voltage, and current in real-time, which can extend battery life and prevent degradation. Furthermore, AI-powered navigation systems can plan the most energy-efficient routes by considering factors like traffic, weather, and topography, helping to alleviate “range anxiety” for drivers. AI algorithms can even optimize charging schedules to align with renewable energy availability and reduce strain on the power grid.

The transition to a software-defined, AI-powered future is no longer a choice – it’s a necessity for survival and growth in the automotive sector. The question for every business in this ecosystem is no longer if they will adopt AI, but how quickly they can adapt to stay competitive.

References:

- How GM and Autodesk are using generative design for vehicles of the future

- Visual Inspection AI: a purpose-built solution for faster, more accurate quality control

- Chats with Your Car: Integrating Large Language Models on Wheels

- A.I. in Automotive: L.L.M.’s in Vehicles

- AI will protect global supply chains from the next major shock

- From Reactive to Proactive: How AI-Driven Supply Chains Weather Every Storm

- AI Drives Automotive Market to $21 Billion Future by 2030

- 5 Ways AI Is Helping Spur the EV Era